Precision Dispensing Reinvented: Inside Contriu’s Plastic Old US Style Glue Cylinder Design

In precision manufacturing, adhesive dispensing has become an integral part of modern electronic assembly, semiconductor packaging, optical bonding, and general industrial production. Regardless of how advanced equipment becomes, the quality and reliability of adhesive delivery still depend heavily on the performance of the dispensing consumables used upstream. Among these, the Plastic Old US Style Glue Cylinder remains one of the industry’s most trusted configurations—valued for its stable dispensing characteristics, compatibility with a wide variety of adhesives, and durability in both automated and manual dispensing systems.

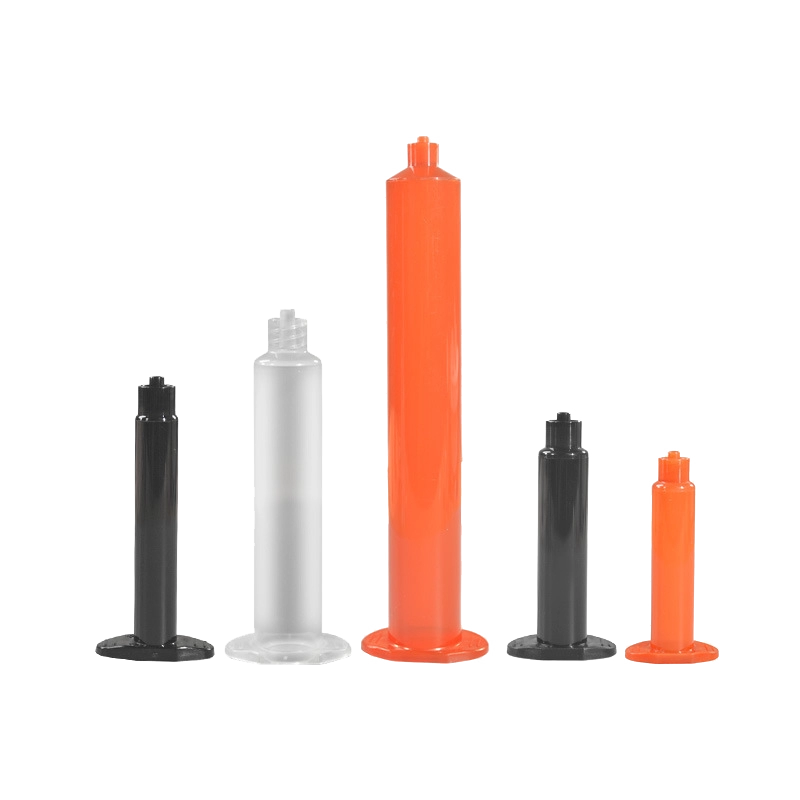

As a specialized manufacturer in precision dispensing consumables, Contriu has engineered its Plastic Old US Style Glue Cylinder series with a focus on consistency, chemical resistance, and optimized material flow. Through the use of high-quality polypropylene (PP) and a color-coded transparency system, Contriu provides a versatile solution capable of satisfying the broad spectrum of adhesive dispensing needs found in electronics, photonics, automotive, and general industrial applications.

A Classic Structure Optimized for Modern Industrial Demands

The naming “Old US Style” originates from a historically standardized cylinder geometry widely used across American industrial assembly lines. Its dimensional stability, ergonomic shape, and compatibility with various air-powered dispensing systems made it one of the most enduring syringe formats in the global market.

Contriu’s version maintains this legacy while refining the design through modern manufacturing technologies. The PP cylinders offer:

Excellent dimensional stability for smooth piston movement

High internal surface finish to minimize flow resistance

Consistent wall thickness to withstand pneumatic dispensing pressure

Chemical resistance to a wide range of industrial adhesives and solvents

These characteristics allow the Contriu cylinders to deliver predictable performance even under continuous-duty, high-frequency industrial operation.

Transparent Cylinders: Designed for Universal Glue Applications

The transparent Plastic Old US Style Glue Cylinder represents the most versatile model in the series. Its optical clarity provides operators with immediate visual confirmation of:

Adhesive level

Glue flow uniformity

Entrapped air bubbles

Contamination or sediment

This makes it especially suitable for general-purpose adhesives used across electronics and assembly applications, including:

Electronic packaging glue

Conductive adhesives

Flux

SMT patch red glue

Lubricating oil

Paint and coatings

UV-resistant adhesives (short-term use)

Transparency provides practical operational benefits, allowing technicians to monitor dispensing consistency and quickly adjust pressure or dispensing parameters.

Black Cylinders: Precision Control for UV-Sensitive Materials

In applications involving UV glue, light-curing adhesives, or compounds sensitive to photochemical reactions, light exposure must be strictly controlled. Contriu’s black PP glue cylinder offers:

Complete light shielding to prevent premature curing

Material stability under high-intensity UV environments

Consistent dispensing rheology across production cycles

Controlled adhesive protection during both short-term and extended use

Black cylinders are essential in industries such as:

Optical module assembly

Fiber connector bonding

Smartphone glass and lens bonding

LED module production

Resin casting and encapsulation involving UV-curing chemistries

Without proper UV protection, even brief exposure can alter viscosity, curing behavior, or chemical stability. The black cylinder eliminates this risk completely.

Amber Cylinders: Balanced UV Protection for General Use

The amber-colored glue cylinder provides partial UV filtration, making it suitable for standard UV protection tasks while still allowing moderate visibility of the adhesive level. This configuration is widely used for:

Materials requiring short-term UV shielding

Production environments with scattered UV light sources

Medium-sensitivity UV adhesives

Applications where visual monitoring is still important

However, it is not recommended for long-term storage of UV glues. While amber PP provides a protective barrier, extended UV exposure could eventually impact material stability.

Material Excellence: Why Polypropylene (PP) Is the Ideal Choice

Contriu manufactures the entire glue cylinder series using industrial-grade PP, chosen specifically for its balance of strength, flexibility, and chemical stability. PP offers:

High resistance to solvents, fluxes, oils, and industrial chemicals

Low moisture absorption to maintain adhesive purity

Non-reactive surfaces to avoid glue contamination

Structural resilience under cyclic pneumatic pressure

Low-cost scalability without compromising product performance

The material supports both disposable and controlled-reuse workflows, depending on factory SOP requirements.

Engineered for Compatibility Across Dispensing Platforms

The Plastic Old US Style Glue Cylinder by Contriu is designed for seamless integration into:

Pneumatic dispensing machines

Automated SMT glue dispensers

Manual dispensing guns

Robotic dispensing arms

Precision micro-dispensing systems

The standardized dimensions and consistent PP molding ensure cylinder interchangeability with global adhesive dispensing systems, making Contriu’s cylinders a preferred choice for OEM equipment manufacturers and aftermarket production environments.

Contriu: Advancing Dispensing Consumables with Engineering Precision

As an industry leader in fluid dispensing accessories, Contriu emphasizes technological consistency, process safety, and product reliability. Its Plastic Old US Style Glue Cylinder reflects:

Engineering-driven manufacturing standards

Material science knowledge applied to practical workflows

A deep understanding of adhesive characteristics and application methods

Commitment to supporting precision manufacturing environments

Contriu continues to innovate in the field of dispensing consumables, helping factories reduce waste, increase process stability, and improve long-term production efficiency.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness