Optimizing Industrial Production with Casting CNC Machining

In modern manufacturing, achieving high precision, consistency, and efficiency is critical for competitiveness. Casting CNC machining has emerged as a cornerstone process for producing complex metal components with tight tolerances, combining the flexibility of casting with the accuracy of CNC machining. Jiangxi Hongdu Precision Machinery, a leading Chinese manufacturer, specializes in delivering superior casting CNC machining services to industrial clients worldwide.

1. Understanding Casting CNC Machining

Casting CNC machining is a hybrid manufacturing approach that integrates metal casting techniques with computer numerical control (CNC) machining. The process typically involves:

Casting the Raw Component: Molten metal is poured into molds to create the rough shape of the part. Common casting methods include sand casting, investment casting, and die casting.

CNC Machining for Precision: Once cooled and solidified, the cast part is refined using CNC milling, turning, or drilling, ensuring exact dimensions, surface finish, and tolerances.

This combination allows manufacturers to produce complex geometries that would be difficult or costly with conventional machining alone, while maintaining high dimensional accuracy and surface quality.

2. Advantages of Casting CNC Machining

Casting CNC machining offers several advantages that make it indispensable in industrial manufacturing:

Cost Efficiency: Rough casting reduces material waste and machining time, lowering production costs.

Complex Geometry: Intricate designs such as internal cavities, thin walls, and undercuts are achievable.

High Precision: CNC finishing ensures tolerances down to microns for critical applications.

Material Flexibility: Compatible with metals such as aluminum, stainless steel, brass, and titanium.

Scalability: Suitable for both small batch prototyping and high-volume production.

By combining casting and CNC machining, Jiangxi Hongdu enables clients to maximize design freedom without compromising precision.

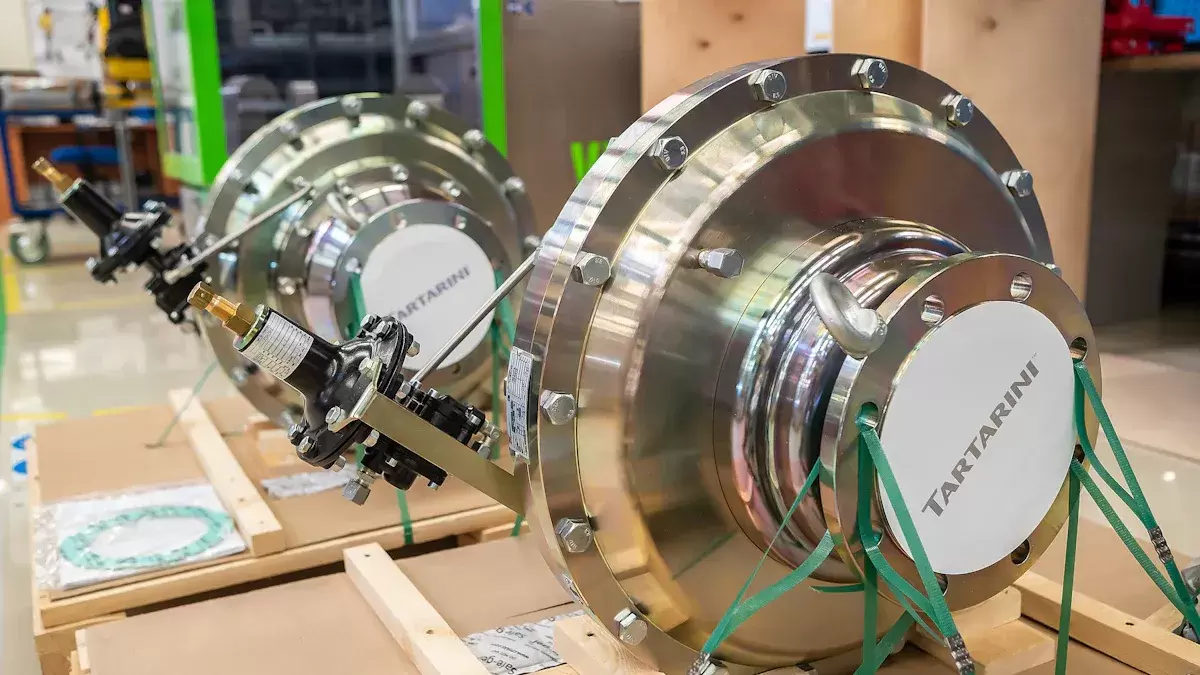

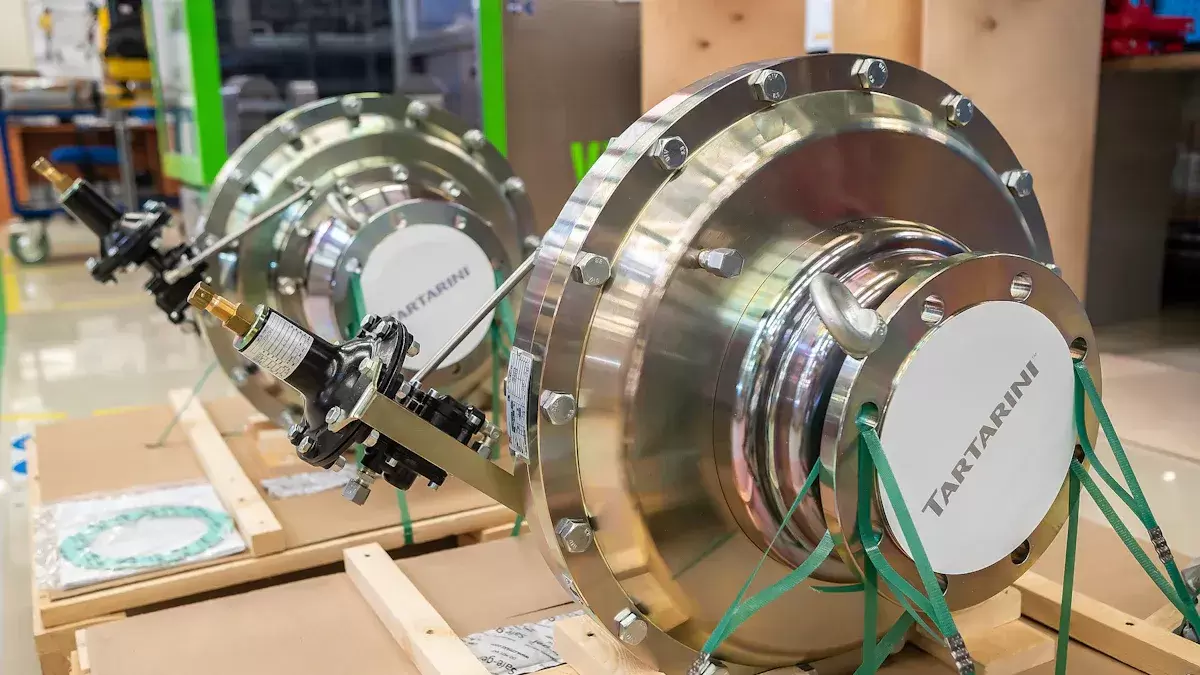

3. Applications Across Industries

Casting CNC machined components are essential in multiple industries, including:

Automotive: Engine blocks, transmission components, and suspension parts requiring complex geometry and high strength.

Aerospace: Lightweight structural components, brackets, and housings where accuracy is paramount.

Industrial Equipment: Precision gears, pump housings, and machinery components.

Medical Devices: High-tolerance surgical instruments and orthopedic implants.

Energy & Power Generation: Turbine parts, valves, and high-temperature components.

Jiangxi Hongdu’s expertise ensures that parts meet strict industry standards, providing reliable performance across these critical applications.

4. Why Choose Jiangxi Hongdu Precision Machinery

Jiangxi Hongdu Precision Machinery stands out for its technical expertise, advanced equipment, and strict quality control. Key differentiators include:

Advanced CNC Machinery: Multi-axis CNC milling, turning, and grinding machines for precision finishing.

Casting Expertise: Extensive experience with aluminum, stainless steel, and other alloys to achieve optimal casting quality.

Quality Assurance: ISO-certified processes, dimensional inspections, and surface quality testing for every part.

Customization Capability: Ability to produce tailor-made components based on client specifications.

Rapid Turnaround: Efficient workflow from casting to final machining, reducing lead times without sacrificing quality.

By integrating casting proficiency with CNC precision, Jiangxi Hongdu provides a one-stop solution for industrial clients seeking high-quality, cost-effective components.

5. Sustainability and Innovation

Jiangxi Hongdu is committed to sustainable manufacturing practices. Advanced material usage, efficient energy consumption, and precision casting reduce waste. Additionally, the company invests in R&D for advanced alloys, automated machining, and smart manufacturing, ensuring clients receive the latest technological advantages in component production.

Conclusion

Casting CNC machining represents the intersection of efficiency, precision, and flexibility in modern manufacturing. By leveraging advanced casting techniques and CNC finishing, Jiangxi Hongdu Precision Machinery empowers industries to produce complex, high-precision components at competitive costs.

For industrial partners, Jiangxi Hongdu provides a trusted, high-quality solution for both prototype and large-scale production needs. When reliability and precision matter, their casting CNC machining services deliver excellence every step of the way.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- 游戏娱乐

- Gardening

- Health

- 首页

- Literature

- Music

- Networking

- 其他

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness