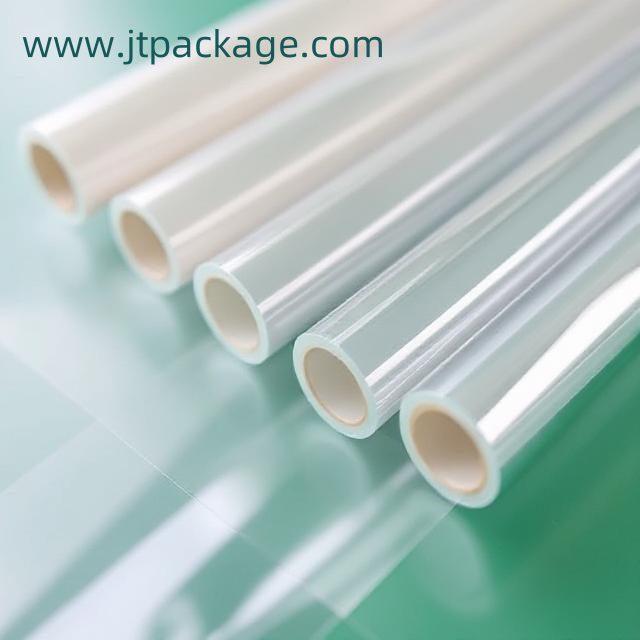

Teams Rely on Crosslinked Shrink Film for Clear and Balanced Presentation

Many packaging teams handle varied items each day, and several of them mention Crosslinked Shrink Film when steady wrapping performance is required. The way Crosslinked Shrink Film settles around different shapes encourages a calm working rhythm, giving staff a sense of confidence as they shift between tasks. Its smooth finish helps objects appear organised, even when movement in the room increases.

Every stage of packaging demands attention, and workers often rely on materials that support consistent motion without forcing them to adjust repeatedly. A wrap that tightens with gentle pressure allows staff to place items down with ease. This steady behaviour reduces unwanted tension and keeps hands moving comfortably during longer periods of activity.

When surfaces vary from soft curves to firmer angles, teams look for a covering that adapts without hesitation. A clean outline enhances visibility, allowing others to recognise goods quickly upon arrival. Workers appreciate coverings that remain calm in shape rather than pulling too sharply. This creates a polished appearance that supports smooth handling across different rooms.

The flow between stations matters as well. When items travel from one step to another, teams want a wrapping method that maintains its form without weakening. A film that stays firm during repeated contact prevents interruptions that slow progress. This sense of steadiness enables groups to focus on upcoming actions instead of fixing small imperfections along the way.

Presentation influences how goods are received, and a neat exterior often gives people greater trust in the work behind each package. A smooth layer that highlights the outline of the item creates an inviting look. Staff value this clarity because it helps them move through tasks without pausing to inspect surfaces. In fast-moving environments, small details like this support larger goals.

A reliable covering also reduces waste caused by unnecessary rewrapping. When film behaves predictably, teams complete tasks with fewer disruptions. Consistency becomes especially helpful during long sessions, when workers benefit from patterns that feel familiar. Calm processes encourage better focus and lighten the mental load of repeated actions.

Many environments handle goods of various sizes, which means a wrapping option that transitions between items helps simplify routines. Workers appreciate materials that offer flexible use rather than requiring separate rolls for each category. Flexibility supports clear organisation throughout the room. When people can shift quickly between different objects, overall flow improves.

Packaging teams often aim to maintain a sense of order, especially when traffic increases. Wrapping that holds its place creates confidence in the handling process. Staff feel more comfortable when each step behaves as expected. This comfort extends throughout the team, helping everyone stay aligned as tasks grow more demanding.

Clean presentation also benefits the moment items reach their next destination. Whether placed on shelves or moved into another room, goods that appear tidy are easier to assess. A clear exterior allows others to judge contents at a glance, shortening the time needed for follow-up actions. People value any detail that lightens their workload while preserving appearance.

Materials that respond smoothly across different settings support more balanced operations. The right wrap helps maintain control even when the day becomes busy. Calm surfaces reinforce a sense of reliability, allowing teams to plan ahead and remain confident during transitions. These qualities build stronger routines and maintain harmony within shared spaces.

Brands such as JTPACKAGE recognise how important steady wrapping behaviour is for teams working through continuous movement. Their focus on clarity, calm handling, and thoughtful presentation supports workers seeking dependable materials. For additional reading, please refer to this page https://www.jtpackage.com/news/industry-news/crosslinked-shrink-films-an-innovative-force-in-packaging.html

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness