Dual-Channel 360° Inspection Technology Ensures Comprehensive Control over Bottle Quality

In today’s competitive manufacturing landscape, precision and efficiency define success. Industries handling high-speed bottling processes—such as pharmaceuticals, cosmetics, food, and beverages—require inspection systems that can guarantee quality while maintaining production speed. The Small Round Bottle Dual-channel Inspection Machine by SanTuo is engineered precisely for this purpose. Combining advanced optical imaging, high-speed data processing, and intelligent defect detection, it provides a powerful solution for ensuring product consistency and reliability on modern production lines.

1. Advanced Dual-Channel Design for Continuous Inspection

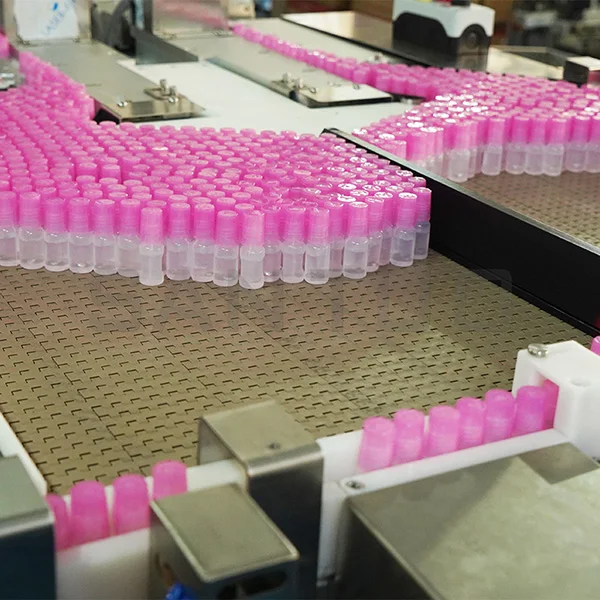

The SanTuo Small Round Bottle Dual-channel Inspection Machine is built around a dual-channel bottle feeding system that enables simultaneous inspection of two bottle lines. This innovative configuration effectively doubles throughput compared to single-lane systems, significantly improving productivity in high-demand production environments.

Each channel is designed with precise bottle-guiding mechanisms to maintain stable movement along the conveyor. This ensures that every small round bottle remains in the optimal inspection position without vibration or deviation, which is crucial for capturing accurate and consistent image data.

2. 360° Multi-Camera Vision System

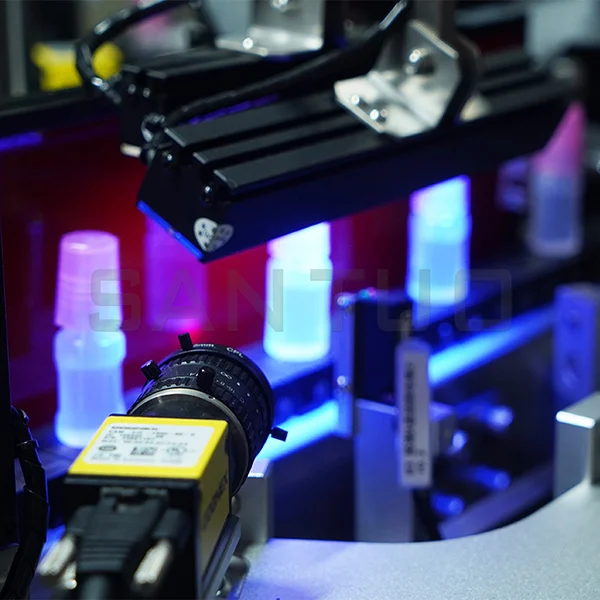

One of the standout features of SanTuo’s system is its multi-camera 360-degree inspection capability. Multiple high-resolution cameras are strategically positioned on both sides of the conveyor channels. As bottles move through the machine, the cameras capture images from multiple angles, ensuring complete coverage of the bottle surface.

This comprehensive visual detection system ensures that every part of each bottle—including the cap, neck, body, and label—is precisely examined. The images are transmitted in real-time to a high-speed image processor, which performs rapid analysis to identify even the smallest irregularities.

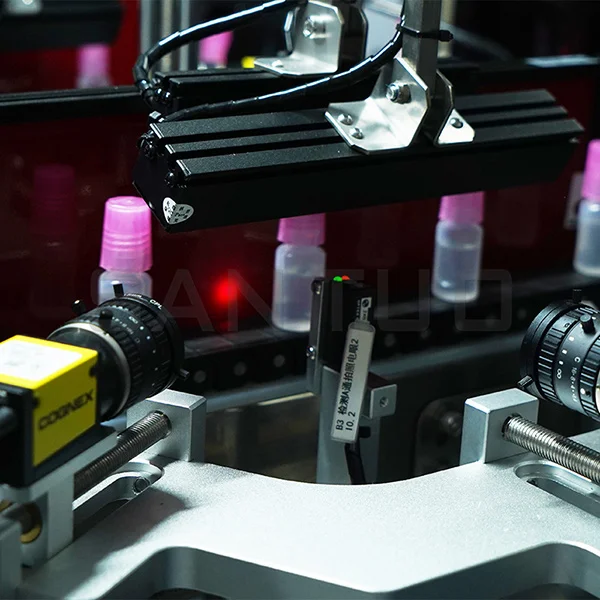

3. Intelligent Image Processing and Defect Identification

At the core of the SanTuo Small Round Bottle Dual-channel Inspection Machine lies an advanced AI-driven image processing system. Using state-of-the-art algorithms, the software can detect a wide range of product defects, including:

Cap defects: high caps, tilted caps, or missing caps

Fill-level deviations: overfilled or underfilled bottles

Surface and appearance flaws: scratches, cracks, dents, label misalignment, or contamination

Once a defect is detected, the system automatically flags the product and triggers a high-speed rejection mechanism that removes defective bottles from the line without interrupting production flow. This ensures that only high-quality bottles continue downstream, protecting your brand’s reputation and reducing waste.

4. Enhancing Efficiency and Reducing Manual Labor

The integration of automation is at the heart of SanTuo’s mission to streamline quality control. The Small Round Bottle Dual-channel Inspection Machine not only enhances accuracy but also dramatically reduces reliance on manual inspection.

Manual inspection is often time-consuming and error-prone, particularly in high-volume environments. By replacing human observation with automated visual analysis, manufacturers can achieve:

-

Higher accuracy rates, as AI detection is consistent and fatigue-free

-

Increased production capacity, thanks to dual-lane operation

-

Lower operational costs, due to reduced labor requirements

-

Improved traceability, with data logs and inspection records for every batch

With SanTuo’s technology, factories can focus their workforce on higher-value tasks while maintaining uncompromised inspection standards.

5. User-Friendly Interface and Seamless Integration

Despite its sophisticated technology, SanTuo has designed the Small Round Bottle Dual-channel Inspection Machine to be easy to operate and integrate. The system features a user-friendly touchscreen control interface that allows operators to adjust parameters such as detection sensitivity, bottle specifications, and rejection timing.

Additionally, the system supports communication protocols for integration into automated production lines, allowing real-time data sharing with upstream and downstream equipment. This connectivity ensures synchronized performance across the entire bottling process, improving overall production management and efficiency.

6. Wide Applications Across Multiple Industries

The flexibility of the SanTuo Small Round Bottle Dual-channel Inspection Machine makes it suitable for a diverse range of applications. Whether inspecting pharmaceutical vials, cosmetic bottles, or beverage containers, the system delivers exceptional performance under varying production conditions.

Typical applications include:

-

Pharmaceutical industry: inspection of vials, oral liquid bottles, and eye drop containers

-

Cosmetic manufacturing: quality control of lotion, serum, and essential oil bottles

-

Food and beverage production: ensuring proper sealing and filling of juice or flavoring bottles

-

Chemical and laboratory packaging: detecting defects in reagent and sample containers

In each of these fields, SanTuo’s dual-channel inspection technology ensures 100% inspection coverage, meeting the rigorous demands of modern quality standards.

7. Why Choose SanTuo’s Dual-Channel Inspection Solution

Choosing SanTuo means choosing reliability, innovation, and long-term value. The Small Round Bottle Dual-channel Inspection Machine offers numerous advantages that make it an ideal choice for manufacturers aiming to improve their production lines:

-

Dual-channel operation for high-speed efficiency

-

360° visual inspection with multi-angle coverage

-

AI-based defect detection for enhanced accuracy

-

Automatic rejection of defective products

-

User-friendly operation and easy system integration

-

Robust design for long-term, stable performance

SanTuo continues to innovate inspection technologies that help manufacturers enhance quality, reduce costs, and achieve greater operational excellence.

Conclusion

As production lines become increasingly automated, reliable inspection technology is no longer optional—it’s essential. The SanTuo Small Round Bottle Dual-channel Inspection Machine represents the next step in smart manufacturing, offering unmatched precision, speed, and efficiency for quality control.

By utilizing a dual-channel bottle feeding system and a multi-camera 360° detection mechanism, SanTuo ensures that every bottle is carefully inspected from every angle. Defects such as high or tilted caps, improper fill levels, or surface flaws are automatically detected and removed, keeping your production line efficient and your products flawless.

For manufacturers striving for excellence, SanTuo’s Small Round Bottle Dual-channel Inspection Machine is more than just equipment—it’s a reliable partner in building a smarter, cleaner, and higher-quality production process.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- 遊戲

- Gardening

- Health

- 首頁

- Literature

- Music

- Networking

- 其他

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness