If you’ve ever had to manage workers manually filling sponge cake, applying cream, and aligning sandwich pairs all day long—you know the challenges. Introducing a food machine for each task might help a little, but the true breakthrough comes when your entire line works in sync, without stopping, without errors.

That’s the logic behind a full automatic sandwich cake production line, and why so many modern food businesses are making the switch.

What Makes This Line “Fully” Automatic?

Let’s break it down:

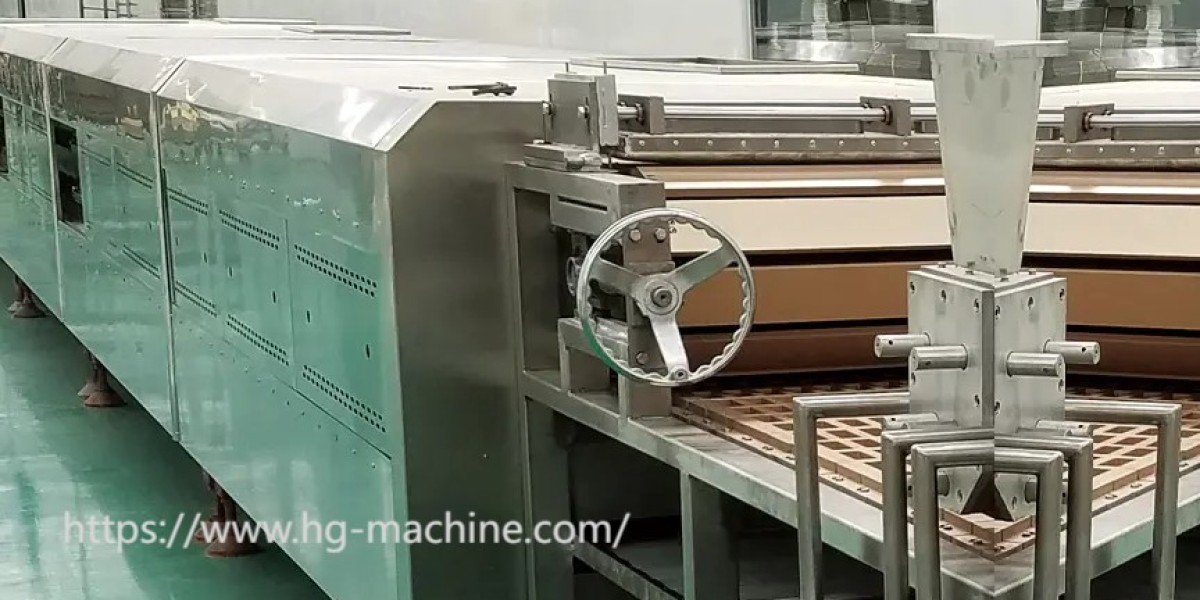

Instead of operators transferring cakes from one station to the next, each module is connected in a continuous system. Machines communicate through smart sensors and PLC controllers to manage timing, temperature, and placement. This eliminates delays, reduces product handling, and boosts hourly output.

Standard steps include:

- Automatic batter feeding and pouring

- Cake baking with conveyor movement

- Precise cream injection using servo-driven heads

- Layer matching and cake alignment

- Ultrasonic or mechanical cutting

- Film or tray packaging integration

And best of all, recipe settings can be stored and adjusted through touchscreen panels. No more guesswork between shifts.

Who Is This Line For?

You don’t need to be a multinational brand to benefit. Central kitchens, regional cake factories, and even startups seeking OEM production contracts can justify the investment.

Common users include:

- Bakery chains launching frozen cake SKUs

- Contract manufacturers producing for supermarkets

- High-end dessert makers expanding into packaged products

Hg-machine clients have used this line to increase daily capacity by 300% while reducing labor by over 50%. The line fits standard factory layouts and supports both chilled and ambient products.

Key Factors to Consider Before Buying

While full automation brings big benefits, buyers should prepare on these fronts:

- Floor space – Measure accurately, including room for loading and cleaning

- Power and air supply – Check specifications for all modules

- Production goal clarity – Know how many units/hour you expect

- Staff readiness – Plan for initial training and adjustment period

With food machine automation, success comes not just from machinery, but also from how well it's integrated. That’s why Hg-machine provides layout design, machine testing, and long-term support—all tailored to your actual products. To explore how a full automatic sandwich cake line fits your production goals, visit hg-machine.com/product/ .