Choosing the Right Banana Rollers Supplier for Your Industrial Needs

Finding a reliable Banana Roller supplier is crucial for industries that depend on web guiding, tension control, and precise alignment of materials. Banana rollers, also known as bowed rollers, play a significant role in maintaining web stability and preventing wrinkles or misalignment during production processes. They are especially useful in applications involving paper, plastic film, textiles, or nonwoven fabric.

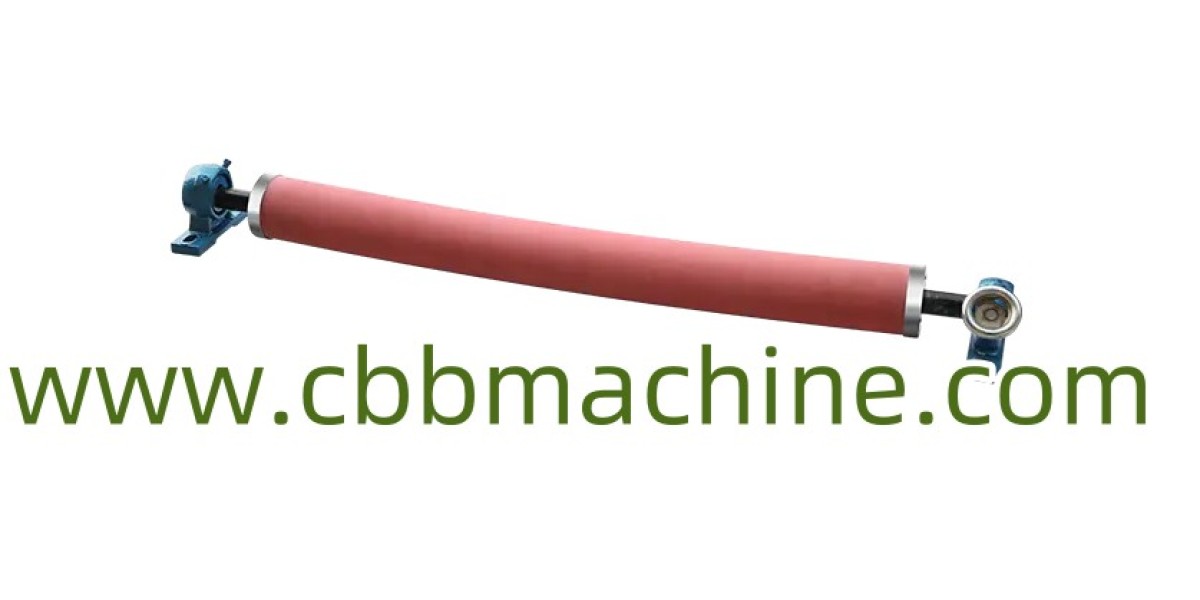

A banana roller is designed with a slightly curved structure, which creates a natural spreading effect on the web as it passes over the roller. This curvature helps eliminate slack and ensure even tension distribution across the web width. The effectiveness of this roller depends largely on the build quality and precision with which it is manufactured.

Working with an experienced banana rollers supplier means more than just purchasing equipment—it means having a partner who understands the technical requirements of your application. A well-designed banana roller can improve process efficiency by reducing product waste, increasing material handling precision, and minimizing downtime due to web alignment issues.

Banana rollers come in different styles depending on the production environment. Some are covered in rubber or silicone to provide enhanced grip, while others are made with aluminum or stainless steel for specific chemical or temperature resistance. Suppliers typically offer customizable options in terms of roller diameter, curvature angle, shaft design, and surface coating. Therefore, the role of a knowledgeable supplier is to recommend suitable configurations based on the customer’s needs.

In high-speed production lines, proper alignment is critical. Misaligned materials can lead to production defects, unnecessary tension, or damage to the final product. Banana rollers work by evenly distributing material tension, which helps ensure smooth processing and accurate results. Their use has become standard in slitting, laminating, printing, and packaging machines, especially where web handling precision is required.

Choosing the right banana rollers supplier involves evaluating their technical knowledge, customization capabilities, and consistency in quality control. A strong supplier relationship also ensures timely delivery, spare parts availability, and responsive after-sales service. When these factors are met, production can continue without unnecessary delays or equipment failure.

Many banana rollers operate with maintenance-free bearings and require minimal upkeep, making them a cost-effective choice over time. However, improper sizing or installation can lead to inefficiencies or mechanical stress. This makes the supplier’s support during the design and installation phases an essential part of the process.

Another important consideration is the balance of the roller itself. Dynamic balancing ensures that the roller operates smoothly at high speeds without introducing vibration or instability. A reputable banana rollers supplier should include precision balancing as part of their manufacturing process, especially for rollers intended for sensitive or high-speed applications.

Technological developments have made banana rollers more adaptable to a variety of applications. Modern designs can incorporate adjustable bow angles, making it possible to fine-tune the spreading effect to match the exact requirements of different production runs. This adjustability makes banana rollers even more effective and suitable for multi-purpose production environments.

In conclusion, banana rollers play a crucial role in web processing by maintaining alignment, reducing wrinkles, and ensuring smooth tension control. Choosing a qualified banana rollers supplier is essential for achieving reliable, consistent results. From initial design consultation to ongoing technical support, the right supplier adds value not only through equipment but also through partnership and understanding of your industry.